close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-12-11 Origin: Site

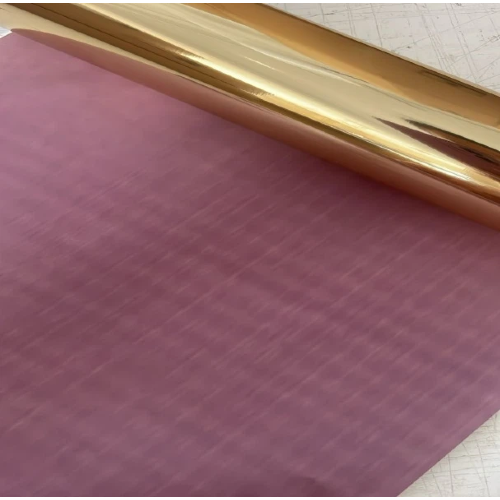

When it comes to achieving the perfect finish on rough-textured substrates such as paper, leather, and PVC, Coffee Back Hot Stamping Foil is a top choice. Known for its luxurious, rich look and feel, this foil offers an impressive visual appeal and is used in a variety of applications, from premium packaging to greeting cards. However, to ensure optimal results, it's essential to use the correct temperature during the hot stamping process. This article will explore the ideal temperature for Coffee Back Hot Stamping Foil, its importance in the stamping process, and how to optimize your stamping settings for flawless finishes.

Coffee Back Hot Stamping Foil is a high-quality decorative foil used primarily for hot stamping applications. Unlike standard foils, this type of foil is designed to be applied to rough or textured materials, such as rough paper, leather, and PVC. The "coffee back" refers to its unique finish, which provides a deep, rich color that pairs perfectly with matte or textured surfaces.

The foil is applied using a heat-based process that transfers the metallic finish to the substrate. This process creates a premium look and feel, making Coffee Back Hot Stamping Foil the ideal choice for high-end packaging, luxury product labels, and bespoke stationery.

Temperature plays a crucial role in the hot stamping process. It ensures that the Coffee Back Hot Stamping Foil adheres properly to the substrate. If the temperature is too low, the foil may not bond well with the surface, resulting in incomplete transfers or weak adhesion. On the other hand, if the temperature is too high, it can burn the foil or the material underneath, leading to unsightly discoloration and uneven finishes.

For Coffee Back Hot Stamping Foil, the recommended temperature typically ranges from 120°C to 160°C (250°F to 320°F). This range is ideal for achieving proper foil adhesion, ensuring a crisp, clean finish without damaging the substrate.

Temperature Range | Ideal Application | Potential Risks |

120°C - 140°C | Best for rough papers, PVC, and leather | Insufficient adhesion or poor transfer |

140°C - 160°C | Optimal for most substrates, including textured surfaces | Risk of discoloration if too high |

Above 160°C | Only for specific high-durability substrates | Overheating and substrate damage |

The ideal temperature for Coffee Back Hot Stamping Foil can vary depending on several factors:

Material Type: Rough paper, leather, and PVC require different temperatures. For example, leather may need a slightly lower temperature than rough paper to avoid burning.

Foil Thickness and Type: The thickness of the foil and the type of finish required (e.g., matte vs. glossy) will also influence the temperature. Thicker foils typically require higher temperatures to bond properly.

Machine Type and Settings: The type of stamping machine you use may have different heating capabilities, so it’s essential to calibrate the temperature settings accordingly.

If the temperature is too low, the Coffee Back Hot Stamping Foil may not adhere to the substrate properly. This can result in incomplete designs, uneven foil transfer, or peeling foil. In some cases, the foil may appear patchy or inconsistent, undermining the premium appearance you aim to achieve.

On the other hand, if the temperature is too high, you run the risk of damaging the substrate or the foil itself. Overheating can cause the foil to burn, discolor, or become too thin, resulting in a subpar finish. Furthermore, high temperatures may affect the texture of materials like leather or rough paper, causing them to warp or deteriorate.

Temperature Issue | Effect on Coffee Back Hot Stamping Foil | Visible Defects |

Low Temperature | Poor adhesion, incomplete transfer | Patchy or incomplete design |

High Temperature | Foil burning, substrate damage | Discoloration, texture change |

Correct Temperature | Optimal adhesion and finish | Crisp, shiny, and long-lasting |

Achieving consistent, high-quality results with Coffee Back Hot Stamping Foil requires precise temperature control. Without the right settings, the finish can vary from one run to the next, leading to inconsistent product quality. By maintaining a consistent temperature, you ensure that each application has the same level of adhesion, gloss, and durability.

Different materials require different heat settings for Coffee Back Hot Stamping Foil. It’s important to understand the material you’re working with to ensure that the temperature is set correctly.

Rough Paper: Rough paper often requires temperatures on the lower end of the spectrum (120°C to 140°C) to avoid burning the paper while still achieving good foil adhesion.

Leather: Leather, being more sensitive to heat, typically requires temperatures between 130°C and 150°C. Too high a temperature can burn or distort the texture of the leather.

PVC: PVC can handle slightly higher temperatures (140°C to 160°C) but still requires close monitoring to avoid warping or discoloration.

Coffee Back Hot Stamping Foil comes in various finishes and thicknesses. The thicker the foil, the higher the temperature needed for proper transfer. If using a metallic or holographic finish, the temperature may need slight adjustment to ensure the foil’s reflective properties remain intact without distortion.

Before starting full-scale production, it’s essential to conduct tests to find the ideal temperature settings for your specific materials and foils. Fine-tuning temperature, pressure, and dwell time ensures that you achieve the best finish with minimal waste and defects.

Possible Causes: Low temperature, insufficient pressure, or incorrect dwell time.

Solution: Increase temperature slightly within the recommended range, adjust pressure, and extend dwell time to ensure proper foil transfer.

Possible Causes: Excessive temperature or improper cooling.

Solution: Lower the temperature slightly and allow the material to cool before handling.

Possible Causes: Uneven heat distribution or inconsistent pressure.

Solution: Ensure that the heating plate and die are clean and uniformly heated. Regularly check machine settings for consistency.

Issue | Possible Causes | Solution |

Foil Not Transferring | Low temperature, insufficient pressure | Increase temperature, adjust pressure |

Foil Peeling/Cracking | Overheating, improper cooling | Lower temperature, allow cooling |

Uneven Finish | Uneven heat, inconsistent pressure | Clean dies, adjust machine settings |

Perform test runs: Always test with small batches to find the right settings before scaling up production.

Monitor temperature regularly: Ensure that the temperature stays consistent throughout the run.

Use high-quality foil: Ensure that you are using premium Coffee Back Hot Stamping Foil to prevent issues like peeling or inconsistent finishes.

Proper maintenance of equipment: Keep stamping machines and dies in good condition to ensure uniform heat distribution and avoid defects.

In large-scale production runs, maintaining a consistent temperature is key. Fluctuations in temperature can lead to varying results, so it’s important to use precise temperature controllers and regularly check the stamping machine.

Using Coffee Back Hot Stamping Foil requires careful attention to temperature control, as it directly impacts the quality and durability of the finish. By properly calibrating the temperature for the specific material and foil, you can achieve a high-quality, long-lasting finish that enhances the appearance of your product packaging, labels, and branding materials. It’s essential to be aware of the risks associated with incorrect temperatures, such as poor adhesion or damage to the substrate. By fine-tuning your settings and ensuring consistency, you can avoid these issues and achieve the best possible results.

At Huasheng New Material Co., Ltd., we specialize in providing premium Coffee Back Hot Stamping Foil and other high-quality foiling solutions designed to meet your specific needs. Our foils are engineered for superior adhesion and durability, ensuring a flawless finish every time. If you’re looking to elevate your product packaging or need customized foiling solutions, feel free to contact us. We are here to help you achieve the perfect look for your products, with the highest standards of quality and precision.

What is the ideal temperature for Coffee Back Hot Stamping Foil?

The ideal temperature typically ranges from 120°C to 160°C (250°F to 320°F), depending on the material and foil thickness.

Why does temperature matter when applying Coffee Back Hot Stamping Foil?

Temperature ensures that the foil adheres properly to the substrate. Too low a temperature can lead to poor adhesion, while too high a temperature can cause burning or damage.

Can I use the same temperature for all materials when applying Coffee Back Hot Stamping Foil?

No, different materials such as leather, rough paper, and PVC require different temperature settings for optimal results.

What happens if the temperature is too high?

If the temperature is too high, it can cause the foil to burn, discolor, or damage the substrate, resulting in poor visual results.

How can I find the right temperature for my project?

It’s essential to conduct test runs on small batches to adjust the temperature, pressure, and dwell time until the best result is achieved.