close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-08-20 Origin: Site

Aspect | Toner Reactive Foil | Traditional Hot Foil Stamping |

|---|---|---|

Setup Costs | Low | High |

Personalization Flexibility | High | Low |

Toner reactive foil works on many surfaces. You can use it on cardstock and labels. This makes it a good choice for different packaging needs. You can also try hot stamping foil and lamination film for other looks.

Toner reactive foil makes shiny, metallic designs on packaging. It uses heat and pressure with a laser printer and laminator. This way is cheap and easy to use. It works well for small businesses or custom projects. You do not need expensive machines. You can pick from many foil colors and finishes. Some choices are metallic, matte, glitter, and holographic. These make your packaging special. Use medium-weight cardstock and solid black toner for the best results. This helps the foil stick well and look shiny. Follow the right steps and settings. Keep your materials clean. Change the heat and speed if needed. This helps you avoid problems like patchy foil.

Toner reactive foil is a special foil that sticks to toner. You need heat and pressure to make the foil stick. You can use a laser printer and a laminator or foil machine. You do not need big or costly machines. You can make shiny, glossy, or holographic looks on paper, cardstock, and some plastics. Toner foiling lets you add color and shine with easy tools.

The market for metallic stamping foil is growing very fast. By 2028, it could be worth about $3.8 billion. Toner reactive foils are growing even faster at 18% each year. Many packaging companies use toner foiling because it is simple and flexible. You can make small batches or custom designs without spending a lot.

Suqian Huasheng New Material Co., Ltd is a top maker of toner reactive foil. You can pick standard or custom foil sheets and core sizes. Their team works hard to make products and service better. You can ask Huasheng for help or visit their factory for tips.

Tip: Save leftover foil sheets for new projects. This helps you save money and cut down on waste.

Toner foiling gives you many ways to make your packaging unique. You can pick from lots of foil colors and finishes. Here are some choices you can try:

Metallic foils come in gold, silver, rose gold, blue, purple, pink, and red.

Matte satin foils have a soft shine in gold, silver, copper, fuchsia, and teal.

Glitter foils have different sparkles and colors, even clear ones.

Iridescent foils give a rainbow or gold shine.

Holographic foils have cool patterns like bubbles or glass.

Gloss pigment foils change color with the toner under them.

You can use toner reactive foil for small orders, custom labels, or event packaging. You do not have to buy a lot at once. You can change designs fast and try new ideas easily.

Toner foiling is good for the environment. The foil is thin and does not stop paper from being recycled. Digital foil printing uses less energy and makes little waste. PET carrier sheets can be recycled in special programs. You can use recycled paper for your packaging. If you use lamination film, check local rules for recycling.

Toner foil gives you bright and bold designs. The foil sticks to toner with heat and pressure. You need to set your machine and pick the right paper for best results. Foil stamping makes a deeper bond and a pressed look that lasts longer. Toner reactive foil is great for small jobs and custom work.

Suqian Huasheng New Material Co., Ltd gives strong support to customers. You can order custom sizes and get help with your packaging. Their team answers questions and helps you pick the right foil sheets.

Customization Option | Description |

|---|---|

Metallic Foil | Shiny colors for fancy packaging |

Matte Foil | Soft shine for classy looks |

Glitter Foil | Sparkle for fun designs |

Holographic Foil | Cool patterns for special packaging |

Gloss Pigment Foil | Color-changing effects for creative projects |

If you want other finishes, Huasheng also has hot stamping foil and lamination film. These work for different packaging styles and needs.

Note: You can ask Huasheng for help with toner foil and other packaging materials.

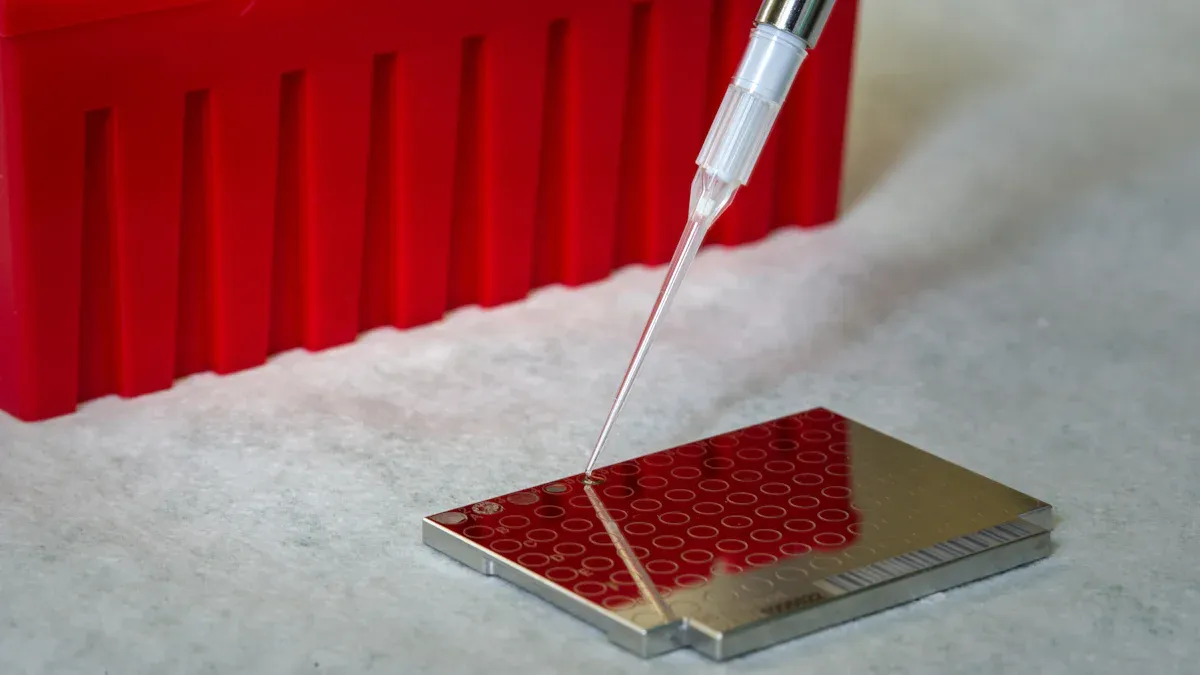

Toner foiling is a smart way to make shiny designs. First, you print your design with a laser printer. The printer uses dry toner powder that sticks to paper when heated. This toner is where the foil will attach.

Next, you put foil sheets on top of the toner areas. You use heat and pressure to make the foil stick. The heat makes the toner soft and sticky. The foil only sticks to the sticky toner spots. When you peel off the foil sheet, the shiny part stays on the toner. This leaves a bright, metallic look on your design. The foil works because it reacts to the heat-activated toner. It does not stick to regular ink or plain paper.

You can use toner foiling on many packaging types. It works well on smooth cardstock, labels, and some plastics. Toner foiling lets you add metallic, holographic, or glossy effects. You get sharp, professional results without expensive tools or dies.

Tip: Always use toner-based printers for the best results. Inkjet printers do not work because foil will not stick to liquid ink.

You do not need fancy tools to start toner foiling. Most people use a laser printer, foil sheets, and a heat source. Here is what you need:

Laser Printer: Pick a desktop laser printer that uses dry toner. This helps the foil stick well. Do not use big business printers or public copiers. They may not work as well.

Foil Sheets: Get toner reactive foil sheets from a trusted supplier like Suqian Huasheng New Material Co., Ltd. Their foils come in many colors and finishes. You can also ask for custom sizes for your project.

Laminator or Foil Machine: A pouch laminator is a good choice. Find one that gets hot enough, at least 300°F. It should let you change heat and speed settings. The Gina K. Designs Fuse Foiling System Laminator is a good example. It heats up fast and works with different papers. It gives even pressure for smooth results. The Xyron Glaminator is another option. It is made for toner foiling and can also laminate.

Heat Press: Some people use a heat press for bigger or thicker materials. Make sure it gets hot enough and gives even pressure.

Here is a table to help you compare equipment:

Equipment Type | Heat Requirement | Features | Best For |

|---|---|---|---|

Pouch Laminator | 300°F or higher | Adjustable heat/speed, handles 10 Mil pouches | Cardstock, labels, small projects |

Roll Laminator | 300°F or higher | Liner take-up, adjustable settings | Large sheets, continuous rolls |

Foil Fuser Machine | Pre-set for toner foil | No adjustments needed, easy to use | Quick, consistent foiling |

Heat Press | 300°F or higher | Even pressure, large surface | Thick or specialty materials |

Other Supplies: You might want a carrier sheet to protect your project. Scissors or a trimmer help you cut foil sheets to the right size.

Note: Always match the core size and roll width of your foil sheets to your machine. Huasheng has 1-inch, 3-inch, and 6-inch core options for different machines.

You can use toner foiling with many packaging materials. Suqian Huasheng New Material Co., Ltd makes toner foil that works with most laminators, foil machines, and heat presses. Their foils also work with hot stamping foil and lamination film. This gives you more ways to make your packaging special.

If you want to try toner foiling, start with a small project. Print your design with a laser printer. Put the foil sheet on top and run it through your laminator. Peel off the foil to see your shiny, custom design. With the right tools and good foil, you can get great results every time.

You want the best results when you try toner foiling on cardstock paper. Medium-weight cardstock works best, especially 80 lb. (216 gsm) cardstock. This type of paper gives you a smooth surface for the toner to stick. You should use a laser printer to print your design with black toner. The foil reacts only to toner, so make sure your design has solid toner coverage. Labels and packaging inserts also work well if they have toner-printed areas. Avoid using inkjet prints or very thin paper, as the foil will not bond properly.

Tip: Always check your cardstock for dust or fingerprints before you start. Clean surfaces help the foil stick better.

You can also use toner foiling for customizing paper products like invitations, business cards, and small packaging. If you want other finishes, hot stamping foil and lamination film offer more options for your packaging needs.

Follow this step-by-step tutorial to get clean, shiny results with toner foiling on cardstock paper:

Print your design using a laser printer. Make sure the toner covers all areas where you want the foil to stick.

Choose your foil color and type. Metallic, matte, holographic, and glitter foils give you different looks.

Cut the foil slightly larger than your design area. This ensures full coverage.

Place the foil colored side up over the toner-printed design.

Cover your project with a protective sheet, such as thin printer paper or vellum.

Warm up your pouch laminator to 250°-300°F. Preheat for at least 20 minutes for best results.

Insert your project into the laminator. Run it through slowly to apply heat and pressure.

Let your project cool before peeling off the foil. Remove the foil gently to reveal your shiny design.

Inspect your work. If you see patchy spots, you can run it through the laminator again.

Common mistakes include using light toner coverage, greasy fingerprints, or a laminator that is not hot enough. Always use solid black toner and preheat your machine. Place a piece of cardstock under your project for better contact.

You can achieve professional results by following these steps. Toner foiling on cardstock paper lets you create custom packaging with metallic accents. Suqian Huasheng New Material Co.,Ltd offers high-quality foil sheets and support for your projects.

You can make your packaging look special by picking the right toner and foil. The toner color changes how the foil looks. Black toner gives the brightest shine. It also makes the biggest contrast. You can use white or colored toner for cool effects. These can give tone-on-tone or strong contrast.

Popular foil finishes for custom packaging include:

Gold and silver foil for a classic, fancy look

Rose gold and copper foil for a soft, rich feel

Holographic foil for shiny, rainbow effects

Matte black with gold foil for luxury packaging

Bright colors like electric blue, fuchsia, and red for bold designs

Earthy colors like olive green, terracotta, and beige for eco-friendly brands

You can use holographic foil to make logos stand out. Matte and glossy foils together add depth to your design. You can use big letters with foil for a bold style. Suqian Huasheng New Material Co.,Ltd has many foil colors and finishes. You can ask for custom sizes to fit your packaging. You can also try hot stamping foil and lamination film for more choices.

Tip: Try different toner and foil mixes on samples before you start a big project.

You might have problems when using toner foiling. Some common problems are patchy foil, uneven sticking, and visible spots. You can fix these with easy steps:

Use lots of toner for better results. Black toner sticks best.

Heat your laminator or heat press to the right temperature. Most foils need at least 250°C.

Clean your paper or packaging before you add foil. Dust and fingerprints can stop the foil from sticking.

Pick good foil sheets from trusted suppliers like Suqian Huasheng New Material Co.,Ltd.

Change your laminator speed and temperature if the foil does not stick well.

Try heating blank paper before printing to help toner stick better.

Humidity can change how much water is in your paper. This can make the paper shrink or stretch when you foil it. It can mess up how the foil lines up and sticks. Keep your paper in a dry place to help with this.

If you need help with custom sizes or fixing problems, you can contact Huasheng’s support team. Their experts can help you learn toner foiling and pick the best products for your project.

Problem | Solution |

|---|---|

Patchy foil coverage | Use lots of toner, heat equipment first |

Uneven adhesion | Clean paper, change temperature or speed |

Registration issues | Control humidity, keep paper dry |

Weak shine | Use black toner, pick good foil |

Note: You can ask Huasheng for help with toner foiling, hot stamping foil, and lamination film for your packaging projects.

Toner reactive foil lets you make custom packaging that looks professional. You do not need fancy tools or special dies. You get many good things from using it:

You spend less money to start and finish projects faster.

You can change designs easily for small or personal jobs.

It works well with printers that use toner and digital setups.

You can make cool effects like two-tone foiling to help your packaging stand out.

Try toner foiling for your next project. You can also look at hot stamping foil and lamination film from Suqian Huasheng New Material Co.,Ltd. These give you even more ways to be creative.

Toner reactive foil works on smooth cardstock and labels. You can use it on some plastics too. It sticks best to toner-printed designs. You can also try it on packaging inserts. Custom cards are another good choice.

Tip: Test a small piece before your big project.

You need a laser printer and toner reactive foil sheets. You also need a laminator or heat press. You do not need fancy machines or dies. Suqian Huasheng New Material Co.,Ltd has foil sheets for most laminators.

Most paper packaging with toner reactive foil can be recycled. The foil is thin and does not stop recycling. If you use lamination film, check your local recycling rules.

Use solid black toner for your design. Preheat your laminator before you start. Clean your paper before you add foil. If you see patchy spots, run it through the laminator again.

Problem | Quick Fix |

|---|---|

Patchy Foil | Use more toner, preheat |

Weak Shine | Use black toner |

You can buy toner reactive foil from Suqian Huasheng New Material Co.,Ltd. They have many colors, finishes, and custom sizes. You can also get hot stamping foil and lamination film for more choices.