close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-04-08 Origin: Site

In the ever-evolving world of textile decoration and apparel design, digital sublimation textile foil printing has emerged as a cutting-edge method that combines the brilliance of metallic finishes with the versatility of digital technology. If you're in the fashion, fabric, or textile printing industry and looking to create eye-catching, luxurious effects on materials like terylene, cotton blends, sari fabric, or polyester, this technique is a game-changer.

At its core, digital sublimation textile foil printing is a heat-transfer process that uses digitally printed designs and metallic foils to embellish textiles. It allows for precise, full-color graphics combined with stunning foil effects that traditionally were only possible through manual hot stamping. This advancement is especially useful for small-batch customization, fashion prototyping, and high-end textile branding.

In this guide, we’ll explore the ins and outs of digital textile foil and how Suqian Huasheng New Material Co., Ltd.—a leading textile foil supplier in China—has perfected this process to meet the growing global demand for premium textile foil rolls, textile foil paper, and hot stamping foil solutions.

Digital sublimation textile foil is a specialized decorative foil used in fabric printing. It is applied using a combination of heat and pressure, often via heat presses or industrial machines, and is specifically designed to bond with digitally printed areas on fabric that have been pre-treated with adhesive or toner-reactive coatings.

This method differs from traditional hot stamping foil techniques by eliminating the need for metal dies or plates, streamlining the customization process, and enabling on-demand production.

Unlike conventional textile printing methods, digital sublimation with foil allows for a metallic, holographic, or iridescent finish on fabrics like terylene, sari, and polyester blends—materials that are commonly used in high-end fashion and interior textiles.

Compatible with terylene, sari, cotton, polyester, and synthetic fabrics

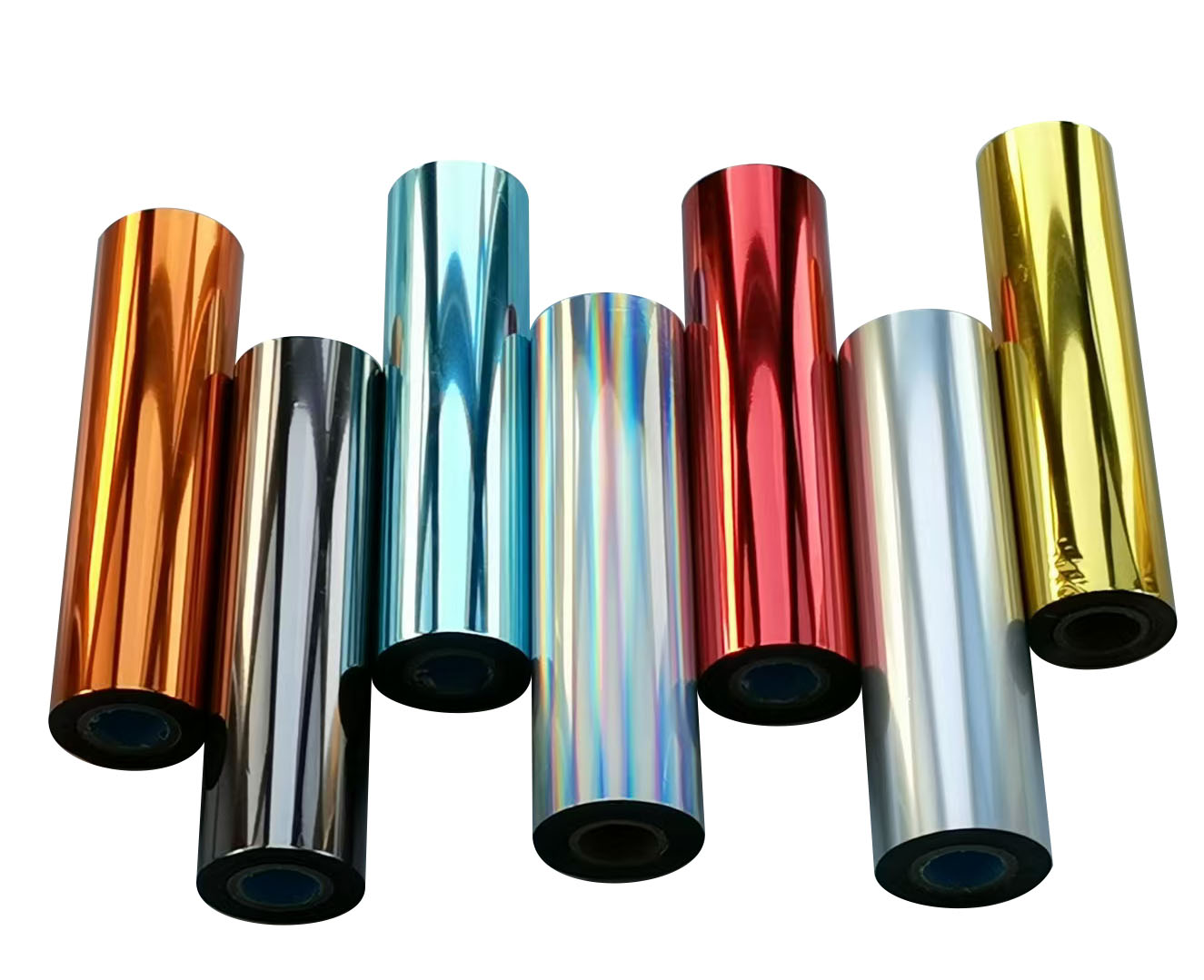

Offers a wide range of finishes: gold, silver, holographic, iridescent, and more

Allows for precision and customization with digital design files

Works seamlessly with textile foil adhesive for strong bonding

Eco-friendly and waste-reducing compared to traditional foil stamping

The process is relatively straightforward, though it requires high-quality textile foil materials and proper application methods for optimal results.

Here’s a simplified breakdown of the process:

Design Preparation: A digital artwork is created and printed onto transfer paper using sublimation ink or toner-reactive methods.

Foil Placement: A sheet or roll of digital textile foil is placed over the printed area.

Heat Transfer: Using a heat press or calendar machine, heat and pressure are applied, which activates the adhesive or toner beneath the foil.

Foil Removal: Once cooled, the foil sheet is peeled away, leaving the metallic design bonded to the fabric.

This method is particularly suitable for fabrics that are difficult to print on using traditional screen printing or dye-sublimation techniques.

Suqian Huasheng offers a wide selection of textile foil rolls and digital foil printing products designed for different applications. Based on their product page, here are some of the top offerings:

This foil is ideal for achieving a bold metallic effect on synthetic fabrics. It adheres beautifully to terylene, cotton blends, and even sari fabric, making it perfect for ethnic wear, fashion labels, and decorative home textiles.

Key Benefits:

High durability against washing

Suitable for screen printing and digital printing

Excellent for fashion and branding applications

This foil adds an iridescent shimmer to T-shirts and casual wear. It's washable, long-lasting, and compatible with most screen-printing adhesives.

These foils are backed by Huasheng’s advanced production capabilities, including 10+ coating lines and a specialized R&D team focused on improving textile foiling technology.

If you're sourcing textile foil supplier options, Huasheng stands out by offering:

Custom sizes and roll widths

Compatibility with 1", 3", and 6" cores

Consistent quality across all hot stamping foil and digital textile foil products

A strong R&D team to support new applications

Eco-friendly manufacturing processes

This modern approach to textile foil printing opens the door to endless creative possibilities. Here are some of the most common applications:

| Application Area | Foil Type Recommended | Fabric Type |

|---|---|---|

| Fashion Apparel | Gold, holographic, iridescent foils | Cotton, polyester, terylene |

| Ethnic Wear (e.g., Sari) | Gold foil, pigment foil | Silk blends, sari fabric |

| Sportswear & T-Shirts | Washable silver or iridescent foils | Cotton, synthetic blends |

| Home Textiles | Semi-transparent or metallic foil rolls | Curtain fabrics, cushions |

| Brand Labels & Hang Tags | Pigment foil, textile foil paper | Synthetic fabric, cardstock |

| DIY Craft Projects | Brush foil, special effect foil rolls | Cotton canvas, felt |

The rise in demand for custom textile foil printing and sustainable production methods makes digital sublimation textile foil a hot topic in fashion and textile manufacturing.

Here are some reasons why:

The fashion industry is moving toward on-demand, zero-inventory production.

Consumers are demanding more personalized and luxurious finishes.

Digital methods reduce waste and setup time compared to traditional foiling.

Foil printing offers high perceived value with minimal material cost.

Using textile foil correctly is key to achieving professional results. Here are general usage tips:

Always test the foil on your specific fabric first.

Make sure your textile foil adhesive is compatible.

Apply even heat and pressure—typically between 160°C and 180°C.

Wait for the fabric to cool before peeling off the foil for clean results.

Store foil rolls in a dry, cool environment to prevent adhesive degradation.

Digital foil printing refers to applying metallic or holographic foils to printed materials using digital technology—no plates or dies required. In the textile industry, this refers to the process of applying foil to fabrics via digital pre-treatment methods such as toner-reactive or sublimation printing.

This enables highly customized, low-volume runs with minimal waste—ideal for startups, fashion designers, and personalized product lines.

| Feature | Digital Sublimation Textile Foil | Traditional Hot Stamping Foil |

|---|---|---|

| Setup Time | Minimal | High (requires dies) |

| Customization | High | Limited |

| Best For | Short runs, personal designs | Mass production |

| Material Compatibility | Terylene, sari, synthetic fabrics | Paper, leather, plastic |

| Environmental Impact | Lower waste, energy-efficient | Higher waste |

While digital sublimation textile foil is a top choice for fashion and textile applications, Huasheng also offers related high-impact decorative foils:

Cold Stamping Foil for Fabric Packaging – Great for adding metallic layers to boxes, hang tags, and product labels.

Reflective Tape for Textile Safety Gear – Ideal for sportswear, uniforms, and outdoor clothing needing visibility enhancements.

These products complement textile foil printing workflows and offer additional value for manufacturers looking to expand their product lines.

A1: Fabrics like terylene, polyester, cotton blends, and sari fabric respond well to digital sublimation foil, especially when pre-treated with adhesive or toner-reactive coatings.

A2: Yes, when properly applied with compatible adhesives and heat settings, digital textile foil is durable and washable. Always follow care instructions for best results.

A3: A heat press is highly recommended for consistent results, but for small DIY projects, a household iron with temperature control can work with caution.

A4: Ensure that your textile foil adhesive is compatible with your fabric and that heat and pressure are uniformly applied during transfer.

A5: Textile foil is specifically engineered for fabrics, offering flexibility and wash resistance. Hot stamping foil is traditionally used on paper, plastic, and leather.

A6: Suqian Huasheng New Material Co., Ltd. is a leading textile foil supplier offering a wide range of textile foil rolls, digital textile foil, and hot stamping foil for various applications. Visit laserfoils.com for more.

Digital sublimation textile foil is revolutionizing the textile printing industry by offering a perfect blend of creative freedom, cost-efficiency, and environmental friendliness. With the growing demand for personalization and premium finishes, it's no surprise that designers, fabric manufacturers, and textile printers are turning to this modern solution.

Suqian Huasheng New Material Co., Ltd. continues to lead the way in textile foil printing innovation, providing top-tier textile foil paper, digital textile foil, and hot stamping foil that meet the demands of today’s fast-paced, quality-driven market.

Ready to add luxurious metallic effects to your fabrics? Explore Huasheng’s collection of textile foil rolls and experience the future of textile decoration today.