close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-08-11 Origin: Site

You can trust Laser Foils to deliver vibrant, durable finishes that help your brand shine in a competitive landscape.

Foil printing adds shiny, colorful foil to surfaces like paper, plastic, and fabric using heat, pressure, or glue to create eye-catching designs.

There are three main foil printing methods: hot foiling for embossed effects, cold foiling for fast, flat finishes, and digital foiling for detailed, customizable prints.

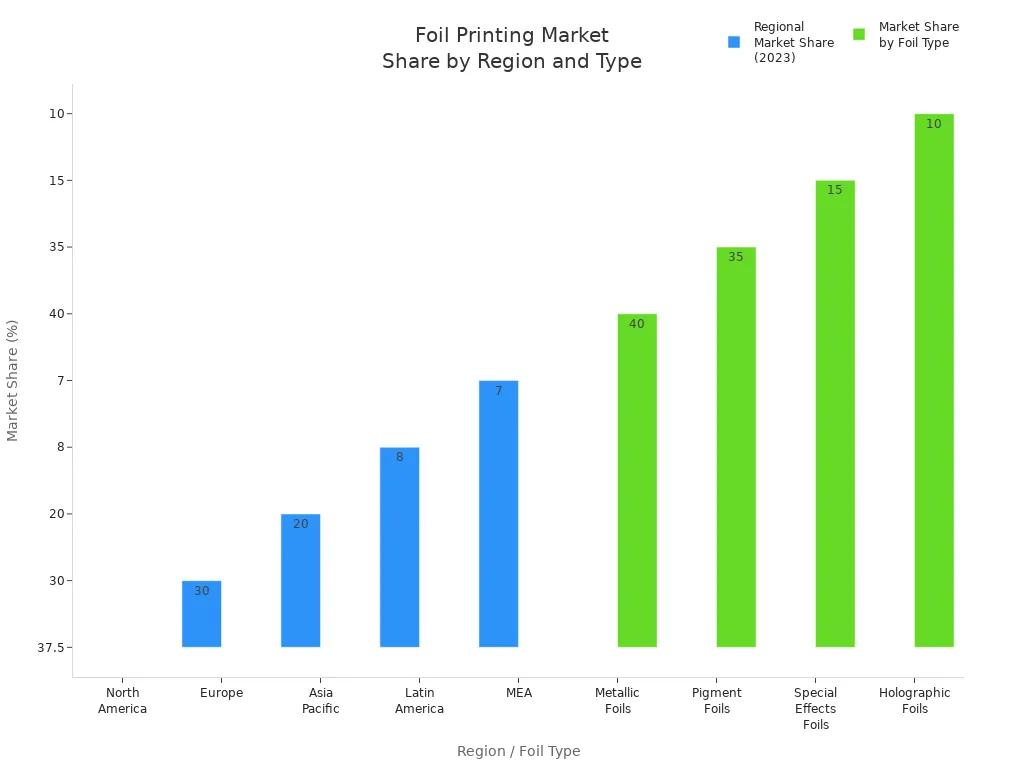

Choosing the right foil type and surface is key; metallic foils add luxury, holographic foils create color shifts, and matte foils offer subtle looks.

Foil printing makes products look premium, lasts longer by protecting prints, and works on many materials, helping brands stand out.

Proper care, like keeping foil prints dry and away from sunlight, helps maintain their shine and durability over time.

Foil printing is a specialized technique that transfers metallic or pigmented foil onto surfaces such as paper, plastic, textiles, or leather. You achieve this effect by using heat, pressure, or adhesive, depending on the method. The result is a vibrant, reflective finish that elevates the look of your products and packaging. Laser Foils offers customizable colorful foils and tapes, making this process accessible for both industrial and creative projects.

You can choose from several main types of foil printing, each with unique advantages. The table below highlights the differences:

Foil Printing Method | Description | Key Characteristics | Distinction from Other Printing Methods |

|---|---|---|---|

Hot Foiling | Uses a heated metal die to press foil onto the substrate. | Creates a debossed effect; tactile finish; shows paper texture. | Artisan method; uses heat and pressure; higher cost due to die creation. |

Cold Foiling | Applies adhesive and presses foil onto glued areas without heat. | Faster; no dies needed; works on thin materials; flat finish. | Uses glue instead of heat; no debossing; cost-effective for large runs. |

Prints toner digitally, then uses heated rollers to adhere foil. | No dies; allows intricate details; combines foil with color printing. | Fully digital; precise; customizable; ideal for small batches. |

You see foil printing used in luxury packaging, business cards, invitations, textiles, and promotional materials. Hot foil stamping creates a tactile, embossed effect, perfect for premium products. Cold foil printing works well for high-speed production and detailed images, making it ideal for cosmetics, electronics, and gourmet food packaging. Digital foiling enables fast customization and variable data printing, supporting prototypes and personalized items.

Foil printing stands out for its ability to deliver brilliant, polished metallic effects and intricate designs. You benefit from a wide range of finishes, including metallic, matte, pigment, and holographic foils. These options allow you to match your brand identity and create memorable products.

Metallic foils such as gold, silver, copper, and rose gold add a luxurious touch.

Matte foils provide a subtle, sophisticated look.

Pigment foils offer vibrant, glossy colors for high-impact designs.

Holographic foils create dynamic, iridescent effects that change with lighting.

Special textures and patterns add depth and visual interest.

You can select foil colors and finishes based on your design aesthetic, target audience, and brand message. For example, luxury brands often choose gold or silver, while tech brands may prefer modern palettes. Color psychology also plays a role—blue conveys trust, red signals energy. Customization options from Laser Foils let you match unique brand identities and ensure durability for lasting impressions.

Recent innovations in foil printing technology have improved efficiency and quality. Digital hot foil stamping eliminates the need for dies, reducing setup time and costs. Eco-friendly foils use water-based adhesives and recyclable materials, supporting sustainability. Expanded color ranges and finishes enhance brand appeal. High-speed stamping machines and automation increase production efficiency and consistency. Integration with smart packaging adds interactivity and security, using QR codes, NFC, and anti-counterfeiting holographic foils.

Tip: When you select foil printing for your project, consider the finish, color, and application method to achieve the best results for your brand.

To achieve professional results in foil printing, you need to select the right materials and equipment for your project. The choice of foil, substrate, and machinery directly impacts the quality, durability, and appearance of your finished product.

Common Foil Types and Their Properties:

Metallic Foils: Mimic metals like gold, silver, copper, and bronze. These foils provide a shiny, reflective finish that adds a premium touch to packaging, labels, and textiles.

Holographic Foils: Create shifting, multi-colored effects that change with light and angle. You often see these on security labels, luxury packaging, and promotional materials.

Pigmented Foils: Offer bold, solid colors with a glossy look but less reflectivity than metallic foils. Use these for vibrant, eye-catching designs.

Matte Foils: Deliver a soft, subtle appearance with reduced shine. These foils work well for sophisticated branding and understated elegance.

Essential Equipment for Foil Printing:

Hot stamping machine with precise temperature and pressure controls

Heated metal dies (brass, copper, or magnesium) for detailed designs

UV-curable adhesive systems for cold foil applications

Digital foil printers for on-demand, short-run projects

Quality foils and tapes, such as those from Laser Foils, tailored for specific substrates and effects

Tip: Always match your foil type and adhesive to your substrate—paper, leather, plastic, or fabric—to ensure strong adhesion and a flawless finish.

Laser Foils Product Range and Applications:

Product Type | Application Method | Ideal Substrates | Typical Uses |

|---|---|---|---|

Hot Stamping Foils | Heat & pressure | Paper, leather, plastic, fabric | Luxury packaging, book covers, textiles |

Cold Foils | UV-curable adhesive | Paper, label stocks | High-speed label production, large runs |

Lamination Films | Pressure or heat | Paper, plastics | Gift wrap, decorative packaging |

Reflective Tapes | Adhesive application | PVC, metal, fabric | Safety markings, industrial equipment, vehicles |

Laser Foils offers customizable options in each category, allowing you to achieve the exact look and performance you need for your project.

You can break down the foil printing process into clear, manageable steps. Each method—hot, cold, or digital—follows a similar structure but uses different techniques and equipment.

Hot Foil Stamping Process:

Prepare your foil, which contains multiple layers: a polyester carrier, release layer, lacquer, image layer, metal layer, and adhesive.

Place the foil and your chosen substrate between the stamping plates or cylinders of the hot stamping machine.

Set the machine to the correct temperature (typically 130°C to 200°C) and pressure based on your foil and substrate.

Activate the heated die, which melts the adhesive and release layer, allowing the foil to transfer.

Apply pressure so the die presses the foil onto the substrate, bonding the design permanently.

Remove the foil carrier, leaving the metallic or colored design on your product.

For multi-color or embossed effects, repeat the process with separate dies as needed.

Cold Foil Printing Process:

Print a UV-curable adhesive onto the substrate in the desired pattern.

Apply the cold foil over the adhesive.

Pass the substrate under a UV lamp to cure the adhesive, bonding the foil to the surface.

Remove the excess foil, revealing the finished design.

Digital Foil Printing Process:

Print your design using a digital printer with special toner or ink.

Feed the printed substrate into a digital foil machine.

The machine uses heated rollers to adhere the foil only to the printed areas, creating intricate, customizable effects.

Note: Laser Foils' hot stamping foils excel in luxury packaging and textiles, while their cold foils are perfect for high-speed label production. Their reflective tapes enhance safety and visibility for industrial and transportation uses.

Key Factors for Success:

Maintain precise temperature and pressure settings for consistent results.

Use high-quality foils and adhesives to prevent peeling, smudging, or flaking.

Regularly clean and maintain your equipment to avoid defects and ensure safety.

Always wear protective gear, such as heat-resistant gloves and safety glasses, when operating hot stamping machines.

Troubleshooting Common Issues:

If foil does not transfer, check your die temperature, pressure, and foil quality.

For smudging or incomplete coverage, adjust pressure and ensure the substrate surface is smooth.

To prevent wrinkles, reduce foil tension and use proper roller settings.

Address registration issues by aligning crop marks and minimizing exposure time.

Safety Reminder: Always follow manufacturer guidelines, keep your workspace organized, and never reach inside the machine while it is running.

By following these steps and using the right materials and equipment, you can achieve crisp, durable, and visually stunning foil prints. Laser Foils provides a comprehensive selection of foils and tapes to support every stage of your foil printing process, from creative design to industrial application.

You want your products to stand out and capture attention instantly. Foil printing delivers a premium look with metallic finishes, shimmering effects, and pearlescent surfaces that create a striking first impression. Visual information reaches the human brain much faster than text, so strong visuals on packaging can boost consumer engagement and brand recognition.

Metallic and holographic foils from Laser Foils add dimension, gloss, and a sense of luxury that traditional printing methods cannot match.

Cold foil adhesives and metallic inks provide high pigment density and a wide color range, making your designs vibrant and memorable.

These enhancements increase shelf appeal and can lead to higher sales by creating a sensory experience for your customers.

Laser Foils' holographic foils create color-changing, reflective surfaces that help your products shine and attract attention in any retail environment.

You need your printed materials to last, especially when they face frequent handling or exposure to the elements. Foil printing adds a protective layer that guards against wear, fading, and environmental stress. Hot stamping foils use a multi-layered structure that resists scratching and maintains vibrancy over time.

Digital enhancement foils also provide a barrier that keeps prints looking fresh and intact, even on substrates like paper, cardboard, synthetic, and specialty materials.

Laser Foils' hot stamping foils offer finishes that do not fade or peel, even under sunlight or harsh conditions. This durability ensures your products maintain a professional appearance and reliability, whether used for packaging, textiles, or promotional items.

The solid construction of Laser Foils' products guarantees your designs remain flawless and long-lasting, supporting your brand's reputation for quality.

You can apply foil printing to a wide variety of materials and product types. Flexographic printing works on film, paper, foil, and non-woven substrates, supporting flexible packaging, corrugated boxes, food and pharmaceutical packaging, direct mail, and publishing.

Laser Foils' customizable foils and tapes adapt to different surfaces, including plastics, textiles, ceramics, and metal containers.

Advanced technologies allow you to print vibrant graphics and intricate designs on diverse materials, increasing product visibility and brand promotion.

You benefit from efficient, scalable production and the ability to perform multiple finishing processes in a single pass.

Laser Foils' extensive product range lets you achieve the exact look and performance you need, whether for industrial applications or creative projects.

Choosing the right surface is essential for achieving a flawless foil finish. Smooth, non-porous substrates like coated paper and board allow for sharp, glossy results with excellent adhesion. Rough or textured papers require foils with high opacity and aggressive adhesives to ensure clean transfer. Flexible materials, such as fabrics and leather, benefit from elastic and rub-resistant foils that maintain durability and appearance. Plastics, including PP, PET, PE, and PVC, need surface pre-treatment and plastic-compatible adhesives for optimal results. Glass and ceramics demand careful cleaning and priming to support strong adhesion. Always match your substrate to the appropriate foil type and application method for the best outcome.

Tip: For textiles and leather goods, Laser Foils’ gold sublimation hot stamping foil delivers durable, clear branding. For packaging, transparent holographic cold stamping foils and glossy gold foils enhance visual appeal and brand recognition.

Maximize the effectiveness of your design by considering the printing process, material compatibility, and intended application. Hot foil stamping works well for business cards, book covers, and luxury packaging, providing a tactile, debossed effect. Cold foil printing suits magazines and promotional materials, offering speed and cost efficiency. Digital foil printing enables intricate, customizable designs for branding and event invitations. Holographic foils add multi-dimensional effects, ideal for security features on official documents. Transfer foil printing allows for detailed, multi-color designs on textiles and ceramics.

Use bold, simple graphics for textured or porous surfaces.

Choose fine details and small text for smooth, coated substrates.

Consult with Laser Foils for specialty foils like holographic tapes for security sealing or embossed films for decorative packaging.

Application Area | Recommended Foil Type | Benefit |

|---|---|---|

Textiles | Gold sublimation hot stamping foil | Durable branding |

Packaging | Transparent holographic cold stamping foil, Pigmented foils | Decorative effects |

Safety | Holographic foils, Scratch foils | Security features |

Decorative | Pearlescent foils, Special design foils | Unique visual effects |

Proper care extends the life and brilliance of your foil-printed products. Keep items dry and clean to preserve appearance and adhesive strength. Avoid direct sunlight and UV exposure to prevent fading. Store products at moderate temperatures to avoid expansion or contraction. Handle with clean, dry hands or gloves to prevent scratches and oil transfer. Use protective packaging, such as plastic wraps or tissue paper, to shield from dust and physical damage. For garments, handwash with mild detergent, air dry in the shade, and avoid harsh chemicals or excessive heat. Regularly inspect for damage or discoloration and address issues promptly.

Note: Organize and label your foil-printed products by type and usage to minimize unnecessary handling and maintain their pristine condition.

You gain a premium finish and lasting durability when you choose foil printing for your products. The process uses heat and pressure to transfer metallic or holographic foils, elevating your brand with vibrant colors and luxury effects. Laser Foils’ customizable options help you achieve precise alignment and stunning results across packaging, textiles, and safety applications. Explore industry resources and design guides to refine your technique. Start your next project with confidence and let your products stand out.

You get the best results on smooth, non-porous surfaces like coated paper, plastics, and leather. Textiles and fabrics also work well with specialty foils from Laser Foils. Always test your substrate before starting a large project.

Yes, you can use foil printing for safety and visibility. Laser Foils offers reflective tapes and prismatic foils designed for vehicles, industrial equipment, and safety gear. These products enhance visibility in low-light conditions.

You should match the foil type to your substrate and design needs. Metallic foils suit luxury packaging. Holographic foils work for security labels. Pigmented foils add vibrant color. Consult Laser Foils for expert recommendations.

Foil-printed items need gentle handling. Keep them dry and away from direct sunlight. For textiles, handwash with mild detergent. Use protective packaging for storage. Regular care helps maintain shine and durability.