close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-08-18 Origin: Site

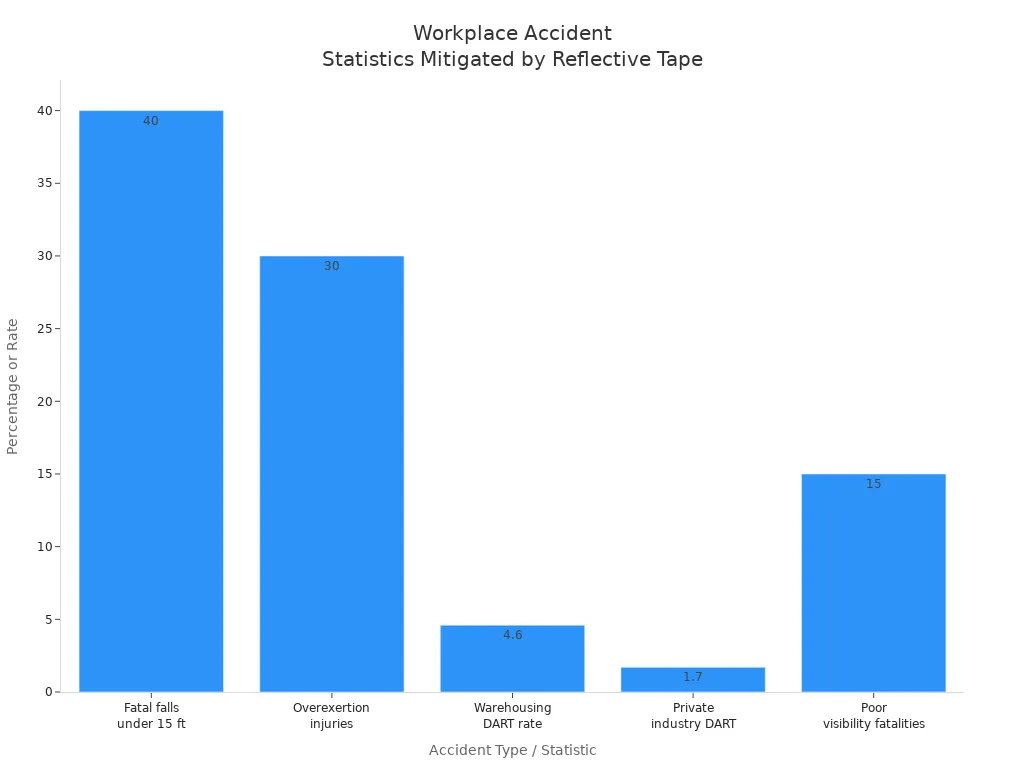

Reflective tape for safety helps lower accidents and follow rules in factories. You see fewer slips, trips, and falls when you use bright floor markings and labels. Visual cues like reflective tape, hot stamping foil, and cold stamping foil help people see dangers, even when it is dark. More than 40% of deadly falls happen from heights under 15 feet. Bad visibility causes about 15% of deaths at work.

You can use reflective tape for safety to mark danger spots, show where equipment goes, and point out emergency exits. These actions help keep your team safe and follow safety rules.

Put reflective tape on floors, edges, and low-clearance spots. This helps stop slips, trips, and falls.

Stick reflective tape on machines and moving parts. It makes them easier to see and helps stop accidents.

Use reflective tape to mark vehicles, forklift lanes, and loading docks. This keeps people safer in busy work areas.

Put glow-in-the-dark and reflective tape on emergency exits and paths. This helps people find their way out safely if the power goes out.

Add reflective tape to safety gear like helmets and vests. This helps workers stand out and stay safe.

Reflective tape helps mark floor zones in your building. It shows where people should walk and where machines move. You put the tape on the floor and pick colors for each hazard or area. The tape is easy to see, even when it is dark. It stays strong for a long time, even with lots of people walking on it.

Warehouses use black-and-yellow tape to warn about danger. Red-and-white tape is near fire safety tools. Green-and-white tape shows where safety stations are in factories. Construction sites use glow-in-the-dark tape for exits. The table below lists hazard types and tape colors:

Hazard Type | Tape Color(s) | Typical Application / Marking Use |

|---|---|---|

Physical Hazards | Black-and-yellow | Marking caution zones, trip risks, and hazardous areas |

Fire Safety Apparatus | Red-and-white | Marking fire safety equipment and flammable materials |

Aisles and Walkways | Black-and-white | Defining aisles and safe walkways |

Safety Stations | Green-and-white | Indicating safety stations |

Dangerous Equipment | Reflective tapes | Highlighting edges and dangerous parts of machinery and equipment |

Low-Light Visibility | Reflective or glow-in-the-dark tape | Marking exits, pathways, and hazards in low-light conditions |

You need to follow OSHA and ANSI rules for marking floors. OSHA says you must use color codes for hazards. You also have to mark aisles and keep floors safe. ANSI has rules for color codes too. Check the tape often and replace it if it is damaged. Using reflective tape helps stop slips and trips. It also helps workers find safe ways to walk.

Put reflective tape on the edges of platforms and open pits. The tape helps people see drop-offs from far away. Diamond-grade tape is even brighter.

Factories use yellow tape on machine edges. Warehouses put tape around mezzanines. Construction sites use tape near open pits. Tape is also on cones and barriers.

OSHA says you must mark hazards and edges. Use bright colors like yellow or red. Check the tape often to make sure it works. This helps stop falls and injuries.

Put reflective tape on low pipes, overhead conveyors, and temporary things. The tape warns workers about bumping their heads.

Plants put tape on pipes above people’s heads. Warehouses mark low lights and signs. Construction workers wrap tape on scaffolding.

OSHA says to use bright tape for low clearance spots. Yellow and black stripes mean caution. Use strong tape that meets safety rules. This keeps people from hitting their heads and keeps the place safe.

Tip: Use reflective tape with hot stamping foil or cold stamping foil labels. This makes things easier to see and lasts longer in tough places.

Reflective tape for safety helps machines stand out at work. When you put bright tape on machines, workers see hazards faster. This easy step can lower accidents and keep everyone safe.

You should put tape on the edges of big machines. Clean the area first so the tape sticks well. Put tape where people walk or drive near machines. Use colors that match ANSI rules, like yellow for caution or red for danger. Check the tape often to find damage. Change tape right away if it fades or peels.

Tip: Use reflective tape with hot stamping foil labels for better visibility and longer life in tough places.

A study by the Department of Defense showed that using retroreflective tape on equipment lowered crashes and injuries by 44%. Drivers and workers see machines from farther away. This gives them more time to react.

Best Practices for Outlining Machinery:

Clean and dry the area before putting on tape.

Use tape in risky or dark places.

Check tape often and change it if needed.

Follow the maker’s instructions for best results.

Pick strong tape made from PET or PVC.

Moving parts like conveyor belts, robotic arms, and spinning shafts need clear marking. Put reflective tape for safety on these spots so workers notice them, even in dim light. This helps stop injuries and keeps hands and clothes away from danger.

You can also use cold stamping foil for labels on moving parts. These labels stay easy to read and do not wear out fast.

Moving Part | Tape Placement | Safety Benefit |

|---|---|---|

Conveyor Belt Edge | Along both sides | Prevents accidental contact |

Robotic Arm | Joints and endpoints | Highlights movement path |

Rotating Shaft | Around circumference | Warns of spinning hazards |

Stationary equipment like storage racks, tanks, and control panels can blend in. Reflective tape makes these things easy to see, even in low light. This lowers the chance of bumping into them or causing a spill.

Reflective tape is a cheap way to mark stationary equipment. It bounces back light, making hazards clear. New tape types, like micro prismatic and glass bead, shine brighter and last longer. You should check tape every few months and change it if it gets dull.

Note: OSHA and ANSI say you must mark hazards and equipment clearly. Using reflective tape for safety helps you follow these rules and keep your team safe.

Reflective tape for safety is very important for vehicles and people in busy workplaces. You can use it on forklifts, trucks, and loading docks. The tape makes them easy to see, even when it is dark. This helps stop accidents and keeps you following safety rules.

You should put bright reflective tape on forklift lanes and forklifts. The tape helps drivers and people walking see where forklifts go. Using reflective tape for safety makes clear paths and borders. This lowers the chance of crashes, especially where many people work.

Marking forklift lanes keeps drivers and walkers in their own spaces.

Clear lanes make accidents less likely.

Reflective tape helps forklifts stay out of each other’s blind spots.

Marked lines help keep people safe.

Many warehouses use reflective tape to guide people and machines. You can also use hot stamping foil labels on forklift controls or warning signs to make them easier to see.

Tip: Always look at the tape for damage and change it if it fades or peels. This keeps your safety strong.

Industrial vehicles like trucks and trailers need reflective tape to meet safety rules. OSHA and ANSI say vehicles and workers must have high-visibility markings. You must use red and white tape in turns on commercial vehicles. Tape should be 2, 3, or 4 inches wide. Put tape on the sides, back, and top corners of trailers.

Put tape along the sides, covering about half the trailer.

Add tape across the lower back, 15 to 60 inches above the road.

Use white tape in an upside-down “L” on the top back corners.

Mark spots near mud flaps and back fenders.

Check and change tape often to keep vehicles easy to see and following the rules. Cold stamping foil labels can also help mark parts or safety instructions on vehicles.

Loading docks are busy and sometimes dark. You can use reflective tape to mark dock edges, ramps, and barriers. This helps drivers see where to stop and helps workers not fall. Many construction sites use reflective tape to show dock edges and help trucks park right.

Area Marked | Benefit |

|---|---|

Dock Edges | Stops falls and crashes |

Ramps | Helps vehicles move safely |

Barriers | Warns about off-limits areas |

Note: Always follow the newest safety rules and check your tape every few months. This keeps your workplace safe and up to date.

Emergency exits are critical in any industrial facility. You need clear, visible markings to help everyone find their way out fast during an emergency. Reflective and glow-in-the-dark tapes play a key role in guiding people to safety, even when the lights go out or smoke fills the air.

You should mark all exit doors with bright, durable tape. OSHA requires EXIT signs to be easy to see at every exit point. Glow-in-the-dark tape works well because it stays visible in darkness or smoke. Many facilities use peel-and-stick photoluminescent kits that meet NFPA, IBC, UL 1994, and ASTM E2072 standards. These kits mark door jambs, handles, and floor-level exits. You do not need wiring or extra maintenance. This makes it easy to keep your building up to code.

Mark door frames and hardware with glow tape.

Place tape at floor level for visibility in low conditions.

Use high-contrast colors to stand out against walls.

Tip: Combine reflective tape with hot stamping foil labels for extra durability and visibility on exit doors.

Egress paths are the routes people use to leave the building. You must keep these paths clear and easy to follow. Use arrows, footprints, and lines made from photoluminescent or reflective tape. This helps guide everyone, even if the power fails.

Studies show that using these tapes improves evacuation speed and safety. Photoluminescent tape absorbs light and glows for up to 30 hours, meeting ASTM E2072 standards. You can install it on floors, walls, and stairwells. It stands up to heavy foot traffic and does not need much upkeep.

Marking Type | Placement | Benefit |

|---|---|---|

Glow-in-the-dark tape | Along egress paths | Guides people in darkness |

Anti-slip tape | On stairs and ramps | Prevents slips and falls |

Directional arrows | At turns and junctions | Reduces confusion |

Keep your markings bright and free from dirt. Use the same color scheme as your Emergency Action Plan. This helps everyone know what to do in an emergency.

Power outages can happen at any time. You need markings that work without electricity. Glow-in-the-dark floor tape helps people find exits and avoid hazards like stairs or trip points. Anti-slip tape keeps everyone safe, even if the floor is wet.

Best practices for marking evacuation routes during outages include:

Use glow tape on floors and stairs.

Add anti-slip tape in wet areas.

Mark “keep clear” zones to prevent blockages.

Use clear shapes and text, such as arrows and footprints.

Check all markings often and replace them if they fade.

Note: Physical tape markings work better than virtual signs during power loss. Always rely on real, visible tape for emergency guidance.

Suqian Huasheng New Material Co.,Ltd offers a full range of safety marking solutions, including reflective tape, cold stamping foil, and more. You can trust their products to help your facility meet safety codes and keep your team safe during any emergency.

Personal protective equipment (PPE) keeps you safe at work, but it only works if people can see you. Reflective tape makes helmets, vests, and clothing much easier to spot, especially in dark or busy places. You can use this simple upgrade to lower accident risks and meet safety rules.

You should always add reflective stickers or tape to your helmet. Place strips on the front, back, and sides. This helps others see you from every angle. Many workers in construction, airports, and factories use this method. Reflective tape uses special glass beads or prismatic shapes to bounce light back to its source. This makes your helmet shine when headlights or flashlights hit it. Clean your helmet before applying tape. Press the tape down firmly and let it set for a day. Check your helmet often and replace tape if it peels or fades.

High-visibility vests are a must in high-risk jobs. You can boost their power by adding reflective tape around your chest, back, arms, and legs. Place tape in an “X” or “H” pattern on the back for better rear visibility. Use tape on wrists and ankles to show movement. Choose tape that is flexible and comfortable. Make sure it sticks well and lasts through washing. Always follow ANSI/ISEA 107-2020 standards for safety vests. Wash your vest with mild soap and avoid bleach to keep the tape working well.

Tip: Use bonded reflective tape instead of sewn-on tape for more comfort and longer life. Suqian Huasheng New Material Co.,Ltd offers high-quality tape that meets these needs.

Busy work zones need extra care. You should use reflective tape on your PPE and also on barriers, machinery, and walkways. This helps drivers and machine operators spot you quickly. For new workers or visitors, use vests with brighter colors or extra tape. This makes them stand out and keeps everyone alert. If you want even more visibility, combine reflective tape with hot stamping foil labels for a strong, long-lasting effect.

Common challenges include tape peeling, poor fit, and fading. You can solve these by choosing abrasion-resistant tape, cleaning surfaces before application, and checking your gear often. Always pick products that match your work conditions and meet local safety rules.

You can make your workplace safer by putting reflective tape on hazards, equipment, vehicles, emergency exits, and PPE. The table below shows how using reflective tape can lower accidents:

Condition | Reduction in Side/Rear Impacts | Reduction in Injury Crashes |

|---|---|---|

Dark Conditions | 29% | 44% |

Dark-Not-Lighted | 41% | 44% |

Here are some steps to help keep everyone safe: First, look at safety records to find risky spots. Next, set easy-to-understand goals for where to use tape. Check the tape every month and change any that is broken. Ask workers to tell you about new hazards. Keep track of what happens and see if things get better over time.

Reflective tape, hot stamping foil, and cold stamping foil help you follow safety rules and save money. You can keep your team safe and follow the law by picking the right products from Suqian Huasheng New Material Co.,Ltd.

First, clean the area where you want to put the tape. Peel off the paper from the back of the tape. Press the tape down hard so it sticks well. Check the tape often to see if it is still good. If the tape is broken or does not stick, put on new tape. Reflective tape for safety works best when the surface is clean and dry.

Pick tape colors that match safety rules. Yellow means you should be careful. Red is for fire equipment. Green shows where safety stations are. Black-and-yellow stripes warn about dangers. Always follow OSHA and ANSI color rules.

Color | Meaning |

|---|---|

Yellow | Caution |

Red | Fire Safety |

Green | Safety Station |

Black-Yellow | Physical Hazard |

Yes, you can put reflective tape on helmets, vests, and jackets. This helps people see you better in dark or busy places. It makes you easier to spot from far away. Using tape also helps you meet ANSI/ISEA rules for high-visibility PPE.

Check the tape every month to make sure it works. Look for tape that is peeling, faded, or broken. Change the tape right away if it does not shine or reflect light. Checking tape often keeps your workplace safe and follows the rules.

You can use hot stamping foil to make strong labels. Cold stamping foil is good for clear signs. Lamination film helps protect markings from damage. Suqian Huasheng New Material Co.,Ltd has all these safety products for your workplace.