close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-11-25 Origin: Site

Cold foil printing is a unique process that applies metallic finishes to packaging materials without the use of heat. Instead of relying on high temperatures like traditional foil stamping, cold foil utilizes adhesive to transfer the foil onto the substrate, offering several benefits including versatility, cost-efficiency, and superior design possibilities. This article explores how cold foil printing works and how it creates stunning metallic effects without the need for heat.

Cold foil printing is a modern technique that applies metallic finishes to packaging materials without requiring heat. Unlike traditional foil stamping, which uses high temperatures, cold foil relies on an adhesive to transfer the foil onto the substrate. This process offers numerous advantages, including versatility, cost-effectiveness, and the ability to create intricate designs. Here's a breakdown of how cold foil works:

Cold foil uses a specially formulated adhesive to bond the metallic foil to the substrate. The foil only adheres to areas covered by adhesive, creating sharp, clean metallic effects. The adhesive plays a critical role in ensuring the foil sticks securely, offering durable, long-lasting results.

Types of Adhesives: UV-curable adhesives are commonly used for fast curing, while solvent-based adhesives are ideal for non-porous surfaces. Flexographic, lithographic, and gravure printing techniques are typically used to apply the adhesive precisely where it’s needed.

Precision in Design: This adhesive-based method allows for fine details and intricate patterns, ideal for premium packaging where precision is key.

Unlike hot foil stamping, which requires high temperatures to apply the foil, cold foil printing works at room temperature. This key feature offers several advantages:

No Risk of Warping: Cold foil can be applied to heat-sensitive materials like plastics and thin papers, which would typically warp or degrade under heat.

Faster and More Efficient: Cold foil printing eliminates the need for heating systems, reducing setup time and making the process more efficient.

Energy-Efficient: Since no heat is required, cold foil printing uses less energy, making it a more environmentally friendly option.

Cold foil’s room-temperature process makes it suitable for a wider range of substrates than hot foil stamping. It works well with paper, cardboard, and heat-sensitive materials like plastic films.

Paper and Cardboard: Cold foil is ideal for premium packaging in industries like cosmetics, food, and luxury goods, as it creates stunning metallic effects on these materials without the need for high heat.

Flexible Films: Cold foil is also perfect for flexible packaging, as it can be used on plastic films that would melt under the high temperatures of traditional foil stamping.

Cold foil printing enables the creation of intricate designs with high precision. The process allows for the use of various foil finishes, such as metallic, holographic, and pearlescent, giving designers plenty of creative freedom.

Fine Details: Cold foil printing can achieve finer details and more complex patterns compared to hot foil, making it perfect for intricate logos, text, and decorative elements.

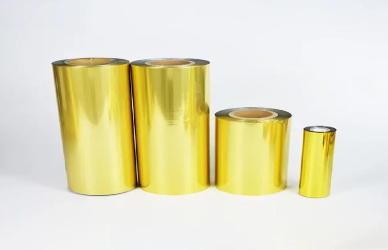

Variety of Foil Finishes: Designers can choose from a wide range of metallic foils, including gold, silver, holographic, and custom colors, allowing for unique, eye-catching designs.

Cold foil printing offers several distinct advantages for packaging, making it a popular choice for producing high-quality metallic finishes. These benefits include no heat usage, cost savings, and environmental advantages. Here’s a breakdown of the key advantages:

Cold foil printing operates without heat, making it ideal for heat-sensitive materials that could be damaged by traditional hot foil stamping.

Works on Delicate Materials: Cold foil can be applied to plastics, thin papers, and synthetic materials without causing warping or distortion, which is a common risk with heat-based methods.

Preserves Material Integrity: Since the process works at room temperature, it ensures that the materials maintain their shape and appearance, even in the case of flexible or delicate substrates.

Broader Material Options: The ability to use heat-sensitive materials expands the design possibilities for packaging, allowing for a wider range of substrates in high-end product packaging.

Cold foil printing is more affordable than traditional foil stamping, thanks to lower equipment and setup costs.

No Need for Expensive Equipment: Cold foil printing requires only a standard printing press with a cold foil unit, eliminating the need for costly dies and heating systems.

Faster Setup: Without the need for heating or complex dies, cold foil printing offers quicker setup times, reducing labor and production costs, especially for short runs or custom designs.

Energy Savings: Cold foil doesn’t require the energy-intensive heating process of traditional foil stamping, reducing energy costs and contributing to overall cost savings.

Cold foil printing offers significant environmental advantages, making it a greener alternative to traditional foil stamping.

Energy Efficiency: Since no heat is required, cold foil printing uses less energy than hot foil stamping, lowering production costs and reducing the carbon footprint.

Lower Carbon Emissions: The lack of high-temperature equipment reduces CO2 emissions compared to the energy-intensive process of traditional foil stamping.

Eco-Friendly Materials: Cold foil printing often uses water-based or UV-curable adhesives, which are more environmentally friendly than the solvent-based adhesives typically used in hot foil stamping. These materials are easier to dispose of or recycle, contributing to overall sustainability.

Cold foil printing is a precise and efficient process that applies metallic finishes to packaging materials without the use of heat. It involves four key steps: substrate and ink selection, adhesive application, foil transfer, and curing. Here's a breakdown of each step in the process:

The first step in the cold foil printing process is choosing the right substrate and ink. The choice of substrate is critical, as it must be compatible with the adhesive and foil transfer.

Substrate Selection: Depending on the packaging needs, materials like paper, cardboard, or plastic films are selected. Paper and cardboard are often used for luxury or retail packaging, while plastic films are common for flexible packaging.

Ink Selection: UV-curable or solvent-based inks are applied to ensure strong adhesion between the adhesive and foil. These inks need to be fast-drying and provide a stable base for the adhesive to bond securely.

In this step, an adhesive is applied to specific areas of the substrate where the foil will be transferred. The adhesive acts as a bond for the foil to adhere to.

Application Methods: The adhesive can be applied using different printing methods such as flexographic, lithographic, or gravure. These methods ensure that the adhesive is precisely applied to the required areas.

Adhesive Types: UV-curable adhesives are commonly used as they cure quickly when exposed to UV light, ensuring fast production times. Solvent-based adhesives are used for non-porous materials, like plastic films, to provide a stronger bond.

Once the adhesive is applied and dried, the cold foil film is transferred onto the substrate.

Foil Application: Cold foil films, which come in various finishes (metallic, holographic, etc.), are applied to the adhesive-coated areas. The foil will only stick to areas where the adhesive has been applied, creating a sharp and defined metallic effect.

Precision in Transfer: The transfer process requires precise control to ensure that the foil adheres to the correct areas. This step is where the intricate designs and fine details of the packaging are brought to life.

After the foil is transferred, the material undergoes a curing process to solidify the adhesive and secure the foil.

Curing Methods: Curing is typically done using UV light or heat. UV light is the most common method, as it quickly solidifies the adhesive, ensuring the foil stays in place. Heat curing is used less frequently but can be effective for certain materials or adhesives.

Securing the Finish: The curing process not only solidifies the adhesive but also ensures the durability of the foil finish, making it resistant to scratching, fading, or peeling.

Cold foil uses adhesive to transfer metallic foil at room temperature, while traditional foil stamping requires high heat to apply the foil to the substrate. Cold foil is more versatile and cost-effective as it can be used on heat-sensitive materials.

Cold foil can be applied to a wide range of materials, including paper, cardboard, and plastic films. It is particularly useful for heat-sensitive substrates that may warp or distort under high temperatures.

Yes, cold foil printing is more energy-efficient than hot foil stamping because it does not require heat. Additionally, many cold foils are recyclable, and UV inks can reduce environmental impact compared to solvent-based options.

Yes, cold foil printing allows for more detailed, intricate designs compared to traditional hot foil stamping. This makes it ideal for premium packaging where fine details and precision are important.

Cold foil printing offers a highly efficient and versatile method for creating stunning metallic finishes on packaging materials. By following a precise four-step process—substrate and ink selection, adhesive application, foil transfer, and curing—cold foil printing ensures exceptional quality and intricate designs without the need for heat. This technique not only preserves the integrity of heat-sensitive materials like plastics and thin papers but also provides a cost-effective, energy-efficient alternative to traditional foil stamping. With its ability to achieve sharp, durable metallic effects, cold foil printing is an excellent choice for brands looking to enhance their packaging with high-end finishes that stand out on the shelf.

content is empty!