close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-07-23 Origin: Site

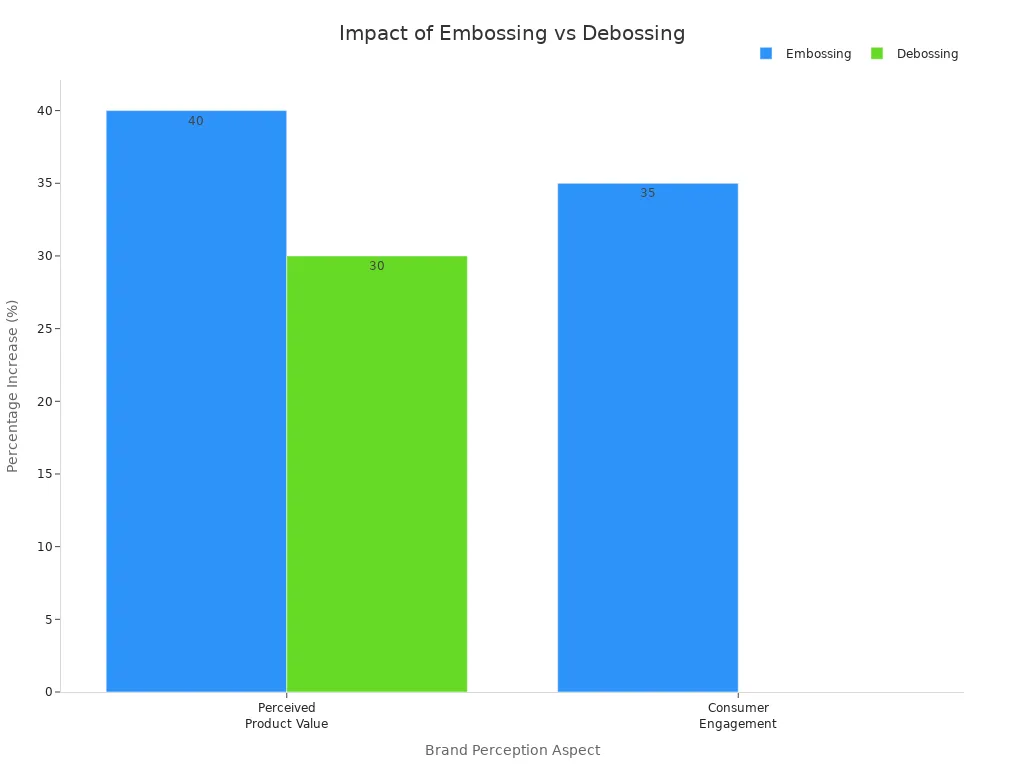

When you look at embossed vs debossed in foil printing, you notice two different effects on cards or packages. Embossing makes the design stick out above the surface. Debossing pushes the design down into the material. Both methods change how your card looks and feels. Studies show embossed or debossed cards can help your brand and get more people interested. Embossed cards often seem fancier. Debossed cards make people think of luxury and skill. If you use hot stamping foil or cold stamping foil, your choice can affect how people see your card or product.

Embossing makes your design stand out from the surface. It gives a bold and 3D look. Debossing pushes the design into the material. This gives a soft and fancy effect. Choose embossing for thick and soft things like heavy paper or leather. Pick debossing for hard things like plastic or stiff cardstock. Foil can make both embossing and debossing look better. Embossed foil sits on the raised parts. Debossed foil fills the pressed-in parts. This gives a shiny, metal look. Embossing costs more because it needs two dies. Debossing is cheaper with just one die. Debossing also lasts longer if you touch the item a lot. Use clear and simple designs with the right materials for best results. Try samples before making many to avoid mistakes and get good quality.

Embossing is a way to make designs stand out. The design is raised above the surface of your material. You need two metal dies that fit together. The material goes between the dies. When pressed, the design pops up. This works on paper, leather, and some plastics. You often see embossing on fancy boxes, book covers, and nice stationery. Blind embossing means you do not use color or foil. It just makes the design raised. If you want a bold look you can feel, embossing is a good choice.

Tip: Embossing works best on thick, soft materials. Heavy paper or leather gives deep, clear designs that feel special.

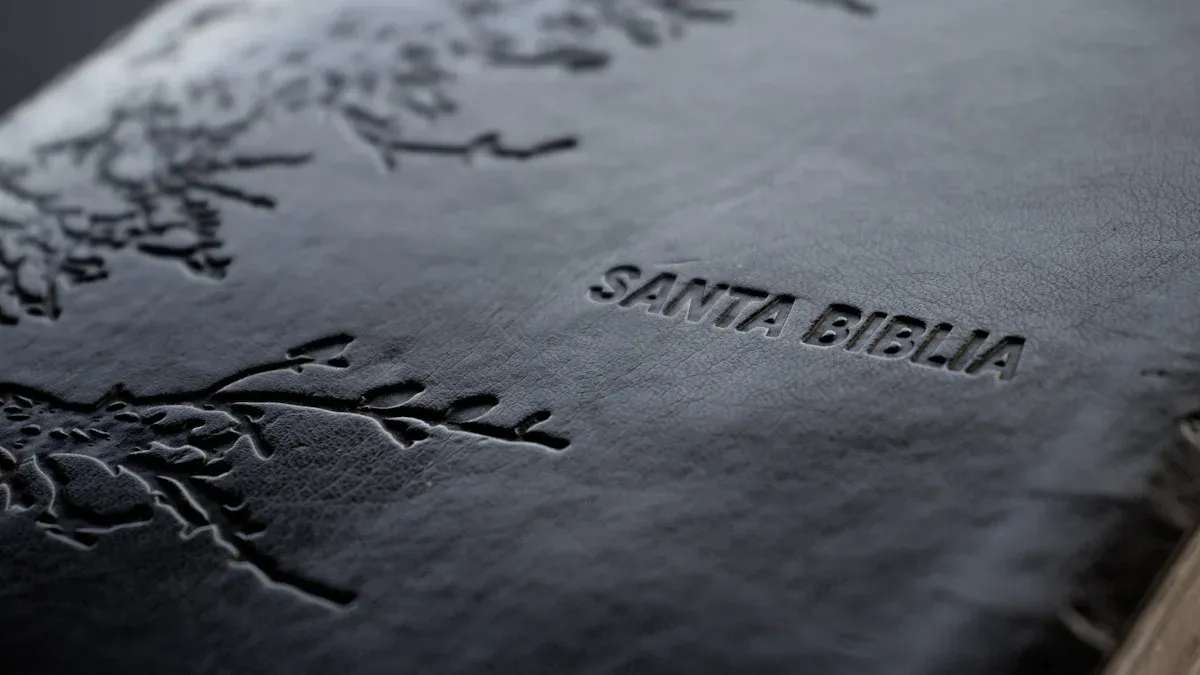

Debossing is different from embossing. The design is pressed down into the surface. This makes a sunken or indented look. You use one die to push the design down. Debossing is used for simple logos on leather, plastic, and fancy labels. If you add foiling, the sunken part can be shiny or colored. This makes your project look deep and classy.

Debossing works well on:

Leather wallets and bags

Plastic bottles and packaging

Fancy paper labels

You can use debossing with hot stamping foil or cold stamping foil. The result is a smooth, nice look that feels fancy.

You may wonder how embossing and debossing are not the same. Here is a table to help you see the differences:

Aspect | Embossing | Debossing |

|---|---|---|

Impression Type | Raised design above the surface | Recessed (indented) design into the surface |

Process | Material pressed into a die from below | Die pressed down from above onto the material |

Dies Used | Two dies (male and female) sandwich the material | Die and counter-die press design into material |

Heat Application | Hot embossing uses heat; cold embossing uses pressure only | Hot debossing uses heat; cold debossing uses pressure only |

Material Suitability | Softer, malleable materials like paper, leather, vellum | Harder, rigid materials like stainless steel, wood, thick plastics |

Equipment Setup | Die presses from below, counter-die from above | Die presses from above to create depression |

When you pick embossing or debossing, think about how you want it to look and feel. Embossing makes a raised texture that catches light. Debossing gives a smooth, sunken look that feels nice. Both can use foiling, but the final look depends on your material and design.

You can use both methods on many things. For example:

Paper and cardstock: Embossing makes packaging and invites look fancy. Debossing gives a simple, modern style.

Leather: Debossing is great for logos on wallets and bags. Embossing gives a raised feel on nice leather items.

Plastic: Both work, but how deep and clear it looks depends on the plastic.

Suqian Huasheng New Material Co.,Ltd has hot stamping foil, cold stamping foil, and digital foil for both embossing and debossing. You can also use lamination film to protect and shine your prints.

Note: How good your embossing or debossing looks depends on your material. Thicker, heavier materials give better results.

Foiling makes your design pop even more. Embossed foil stands out with a 3D look. Debossed foil looks smooth and simple. Your choice changes how people see and touch your brand.

When you compare emboss vs deboss in foil printing, you see how foiling changes the look and feel of your project. Both techniques use foil stamping, but the way foil interacts with the surface is different. You can use hot stamping foil, cold stamping foil, or digital foil from Suqian Huasheng New Material Co.,Ltd to get the effect you want.

Foil embossing combines two steps into one. You press a die into your material to raise the design, and at the same time, you apply a layer of foil. The foil covers only the raised area. This makes the design stand out with a shiny, metallic finish. You can feel the texture with your fingers. The light catches the foil, making your logo or text pop.

In foil embossing, you get:

A raised, 3D effect that you can see and touch.

Foil that sits on top of the raised design, creating a bright, eye-catching look.

A process that uses a die to press and foil at the same time.

You can use hot stamping foil for this process. Hot stamping foil comes in many colors, like gold, silver, and holographic. It works well on paper, leather, and plastic. Digital foil is also an option for short runs or custom prints. Foil embossing is popular for book covers, luxury packaging, and certificates. It gives your product a premium feel.

Tip: Use foil embossing when you want your design to stand out and catch attention. This method works best for titles, logos, and important details.

Foil debossing creates a different effect. You press a die into the material to make a sunken design. Then, you apply foil to the indented area. The foil fills the recessed space, giving a smooth, shiny look that feels deep and rich. This method adds depth and dimension to your print.

In foil debossing, you get:

A sunken, indented design with foil inside the recessed area.

A metallic contrast that highlights the depth of the design.

A process where you deboss first, then apply foil with a heated die.

Hot stamping foil works well for foil debossing. You can also use digital foil for custom or small-batch projects. Cold stamping foil is not usually used with embossing and debossing, but it is great for flat foil stamped designs on labels and packaging.

Note: Foil debossing is perfect for luxury products. It gives a subtle, elegant look that feels high-end.

You have several options for foiling. Each type has its own benefits. Here is a table to help you choose the right foil for your project:

Foil Type | Advantages | Best Use Cases |

|---|---|---|

Hot Stamping Foil | Wide color range, strong metallic shine, works with embossing and debossing, durable finish | Book covers, luxury packaging, labels |

Cold Stamping Foil | Fast, cost-effective for large runs, no need for heated dies | Flat labels, packaging, stickers |

Digital Foil | Quick setup, great for short runs, detailed designs, easy to combine with color print | Custom cards, invitations, samples |

Suqian Huasheng New Material Co.,Ltd offers all these foiling options. You can also use lamination film to protect your foil stamped designs or add extra shine. Reflective tape is another product that adds safety and visibility to your packaging or labels.

You see foiling used in many industries. Embossing and debossing with foil stamping appear on:

Book covers and stationery for a premium, tactile feel.

Labels for wine bottles, cosmetics, and luxury goods.

Packaging for electronics, jewelry, and high-end products.

Certificates, holiday cards, and invitations for a special touch.

Foiling makes your product look elegant and professional. When you combine embossing and debossing with foil stamping, you create a unique experience for your customers. The metallic shine and texture increase the perceived value of your brand.

If you want your print to stand out, choose the right foiling technique. Suqian Huasheng New Material Co.,Ltd can help you select the best foil for your needs.

Embossing makes your package or print feel raised and special. You need to follow some steps to get a neat look with foiling.

First, make your design in a vector program. Put the foiling parts on a layer called “FOIL.”

Next, save your design as a high-quality PDF. Add crop marks and a 1/8" bleed. This helps your embossing and foiling stay lined up.

Make a female die that matches your design’s shape. The female die is what makes the raised parts.

Use a male counterforce to hold the material from the other side. This helps press the design evenly.

Put your material between the female die and the male counterforce.

Press down with an embossing machine. You can use a hand, machine, or heat embossing machine. Pick the one that fits your project.

If you want foil, use hot stamping foil, cold foil, or digital foil from Suqian Huasheng New Material Co.,Ltd. You can add foil while embossing or do it after.

Tip: Always check your design and dies before you start embossing. This helps you avoid mistakes and keeps your foil in the right spot.

Picking the right material is important for good embossing and foiling. Here is a simple chart to show which materials work with each foil from Huasheng:

Foil Type | Compatible Materials |

|---|---|

Hot Stamping Foil | Plastics (ABS, PP, PVC, PET), Paper, Cardboard |

Cold Foil | Paper, Laminated Paper, PET, PP, Plastics, Synthetic Films |

Digital Foil | Plastics, Synthetic Papers (supports embossing effects) |

You can use lamination film to keep your embossed and foiled designs safe. Reflective tape is good if you want your package to be seen easily.

When you use the right materials and steps, your project looks sharp and stands out. Embossing with foiling from Suqian Huasheng New Material Co.,Ltd helps your brand get noticed. If you are not sure which foil or material to pick, you can ask Huasheng’s team for help.

When you pick debossing, you follow some easy steps. First, you make your design on a computer. Use clear lines and simple fonts so it is easy to see. Next, you get a metal die made from brass or copper. Skilled workers carve the die to match your design. You put the die on a strong press. Brands like Kluge or Heidelberg make good machines for this. Some presses can heat up, which helps if you want to add foiling. Place your paper, leather, or plastic under the die. The press pushes the design down into the material. If you want a shiny look, put foil on before pressing. This makes a bright, sunken design that looks great on fancy packages or leather.

Tip: Print your design first, then deboss and foil. This keeps your design neat and stops it from getting ruined.

Debossing uses just one die, so it is faster and easier than embossing. You save time and money, especially if you have lots to make or a simple design. The sunken design does not wear off, so your logo stays clear for a long time.

You can use debossing on many things. Paper, leather, and plastic all work well. For foiling, pick hot stamping foil or digital foil from Suqian Huasheng New Material Co.,Ltd. These foils stick well to the sunken parts and look shiny. If you want to protect your design, add lamination film after debossing and foiling. This keeps your design looking new and nice.

Here is a quick table to help you choose the best foil for debossing:

Foil Type | Best For | Features |

|---|---|---|

Hot Stamping Foil | Paper, leather, plastics | Strong shine, durable finish |

Digital Foil | Short runs, custom projects | Fast setup, detailed designs |

Debossing with foiling gives your products a soft, fancy look. It is a good way to save money and works for many things, like special labels or packaging. If you are not sure what foil or material to use, you can ask the team at Suqian Huasheng New Material Co.,Ltd for help.

If you pick embossing with foiling, your design sticks up and shines. The foil sits right on top of the raised parts. This makes the colors look bright and shiny. Gold, silver, and holographic foils make your logo or words stand out. Gloss coatings make the foil extra shiny, so it pops in the light. Matte coatings give a soft, fancy look. You can feel the raised texture when you touch it. Embossing gives a 3D look that stands out on boxes, book covers, and fancy cards. Lamination film helps protect the foil and keeps it looking new.

Tip: Use embossing with foiling for designs you want people to see and touch. It makes your product look and feel special.

Debossing with foiling makes a design that sinks into the surface and looks shiny. The foil fills the sunken parts, giving a deep, rich look. You see the metallic shine inside the lowered area, which feels fancy and quiet. Gloss coatings make the foil look brighter, while matte coatings make it look calm and smooth. Debossing feels smooth when you touch it. This style is great for fancy packages, leather items, and special labels. You can use reflective tape to make your products easier to see.

You might wonder how emboss and deboss are different with foiling. Here is a table to help you compare:

Feature | Emboss Foil Finish | Deboss Foil Finish |

|---|---|---|

Texture | Raised, 3D, tactile | Sunken, smooth, indented |

Visual Impact | Bold, eye-catching, shiny | Subtle, elegant, refined |

Foil Placement | On top of raised design | Inside recessed pattern |

Best For | Logos, titles, luxury packaging | Labels, leather, specialty goods |

Foil color, gloss, and texture all change how your design looks and feels. Embossing makes your design pop out, while debossing gives a quiet, fancy look. Pick the style that fits your brand and what you want your product to be.

Embossed and debossed foil printing is used on fancy packages. You might see it on boxes for makeup or wine. When you touch the box, you feel a raised or sunken design. This texture makes the package look special and expensive. Foil stamping adds shiny metal to logos or words. This makes the box or card look even more cool. Many brands use these styles to show they care about quality. Suqian Huasheng New Material Co.,Ltd has hot stamping foil and cold stamping foil. These work on paper, plastic, and leather. You can pick lamination film to keep your print safe and new. If you want your package to be easy to see, use reflective tape for safety.

Labels on bottles, jars, and food often use embossed or debossed foil printing. You might see this on wine bottles, coffee bags, or soap labels. The raised or pressed-in design feels different when you touch it. This helps your product stand out and be remembered. Foil stamping makes logos or names shine and look important. You can use these styles on eco-friendly labels or bumpy paper for a cool look. Huasheng’s foils work on lots of materials, so you can make labels that match your brand. Embossed and debossed labels can also help people who are blind by adding braille.

Special things like cards, business cards, and invites look better with embossed and debossed foil printing. When you give someone a card with a raised or sunken design, it feels special. Debossed cards look fancy and new, while embossed foil makes them shiny and bold. You can use these styles for notes, gift cards, or nice notebooks. Huasheng’s digital foil and toner reactive foil help you make custom prints for small orders or parties. If you want your card or print to be noticed, these styles give you lots of fun choices.

Tip: Pick the best foil and material for your project. Suqian Huasheng New Material Co.,Ltd can help you find what works best for packaging, labels, or special cards.

When you want to use embossing or debossing in foil printing, you should think about the price. Embossing costs more because it needs two metal dies. Debossing only needs one die, so it is cheaper. The foil you pick changes the price too. Special foils like holographic or pigment foils cost more than regular metallic foils. If you want to cover a big area with foil, you will pay more for foil and machine time. Printing more items makes each piece cost less. The material you use, like thick paper or leather, can change how fast and easy it is to make your prints.

Cost Factor | Explanation |

|---|---|

Die cost | Embossing needs two dies, debossing uses one; metal dies cost more upfront |

Foil area | Bigger foil coverage means higher material and machine costs |

Foil type | Holographic and pigment foils cost more than standard metallic foils |

Quantity | Larger print runs lower the cost per piece |

Substrate | Material type and texture affect setup and production speed |

Additional processes | Adding foil stamping or die-cutting increases total cost |

Tip: To save money, pick debossing and regular metallic foils for your project.

The material you pick changes how much your foil print costs and how good it looks. Embossing works best on thick paper, vegetable-tanned leather, and metals like aluminum or brass. Debossing is good for thick cardstock and leather, but it does not work well on some plastics or fabrics. Heavy, uncoated paper with a felt finish gives deeper and clearer embossing. Coated or thin paper might crack with heat, but foil embossing can help stop this. The way the paper grain goes is important. Embossing should follow the grain to keep it from cracking. Long-fiber sheets and foil board are great for making packages.

Characteristic | Embossed Foil Print | Debossed Foil Print |

|---|---|---|

Physical Effect | Raised 3D design | Sunken or pressed-in design |

Production Method | Needs two dies, higher cost | Uses one die, more cost-effective |

Material Compatibility | Thick paper, leather, metals, fabrics | Thick cardstock, leather, heavy cotton |

Back Surface Effect | Alters both sides of thin materials | Keeps back surface flat |

Cost Consideration | Higher cost | Lower cost |

You want your embossed or debossed foil print to look neat and professional. Start with vector artwork so your design is smooth and clear. Use flat backgrounds to help your design stand out. Pick dark colors like black or navy to make the design pop. Keep your design simple with big text or logos and clean lines. Thick paper is good for bold designs. Thin paper can show more detail but might tear. You can mix embossing with foil stamping for a shiny look. Try different materials and textures to make your print feel special.

Use vector artwork to make the die.

Simple patterns work best for embossing.

Pick thick, strong paper or leather for good results.

Place your design parts so they look balanced.

Mix foil stamping with embossing for a fancy look.

Note: Suqian Huasheng New Material Co.,Ltd has hot stamping foil, cold stamping foil, and lamination film to help you make cool designs. You can ask their team for help with materials and printing tips.

When you pick between embossing and debossing for foil printing, you should think about what your project needs most. Every project is different and uses different materials. Here are some key things to think about:

Material Compatibility: Thick paper or soft leather works well with embossing. Harder things like metal or plastic are better for debossing.

Desired Visual Effect: Embossing gives a raised look that stands out. Debossing makes a sunken design that looks fancy and calm.

Functionality: Think about how people will use your item. Embossed designs feel bumpy, but debossed ones last longer and stay clear even if touched a lot.

Design Complexity: Simple logos or words look best. If your design is too detailed, it might not show up well, especially with embossing.

Customer Requirements: Pick what fits your brand’s style and what your customers want to see.

Durability and Budget: Embossing costs more because it needs two dies. Debossing is cheaper and lasts longer if your item gets used a lot.

Tip: Try your design on the real material before making a big order. This helps you see how it will look and stops problems later.

This table can help you pick which method is best for your project:

Project Need | Embossing | Debossing |

|---|---|---|

Material Type | Best for soft, thick materials | Good for hard, rigid materials |

Visual Impact | Raised, bold, tactile | Sunken, subtle, refined |

Durability | Prone to wear on raised areas | Lasts longer, less wear |

Cost | Higher (two dies needed) | Lower (one die needed) |

Design Complexity | Simple designs work best | Handles simple, clean designs |

If you want your packaging, labels, or special products to look fancy, Suqian Huasheng New Material Co.,Ltd has hot stamping foil, cold stamping foil, and digital foil. You can add lamination film to keep your print safe and shiny. Their team can help you pick the right foil and method for your project.

For help, contact Suqian Huasheng New Material Co.,Ltd. Their team will help you choose the best foil printing for your project, so your brand looks great and your products stand out.

You can pick embossing or debossing for foil printing. Both ways make your brand look special. Embossing gives a raised design you can see and touch. Debossing makes the design pressed down into the material. Look at the table to compare them:

Feature | Embossing (Raised) | Debossing (Indented) |

|---|---|---|

Visual Impact | Bold, 3D, stands out | Subtle, elegant, refined |

Best Materials | Thick paper, leather | Leather, plastic, paper |

Cost | Higher | Lower |

Think about what you want your project to look like. Also, think about how much you want to spend. Pick the style that fits your needs best. If you need help with hot stamping foil or lamination film, ask Suqian Huasheng New Material Co.,Ltd. The right choice will help your project look great!

Embossing raises your design above the surface. Debossing presses your design down into the material. Both methods work well with hot stamping foil and cold stamping foil from Suqian Huasheng New Material Co.,Ltd.

Yes, you can use foil with both techniques. Foil embossing creates a shiny, raised effect. Foil debossing gives a sunken, metallic look. You can choose from digital foil, hot stamping foil, or cold stamping foil.

Thick paper, leather, and some plastics work best. You get the clearest results on sturdy materials. Suqian Huasheng New Material Co.,Ltd offers foils for many substrates, including packaging film and lamination film.

Yes! Gold, silver, and holographic foils each create a different effect. Glossy foils shine more, while matte foils look soft. You can match foil color to your brand or product style.

Think about your material, design, and budget. Hot stamping foil works for most projects. Cold stamping foil is fast for large runs. Digital foil is great for custom or short orders. You can ask Suqian Huasheng New Material Co.,Ltd for expert advice.

Tip: Try a sample with your chosen foil and material before starting full production.